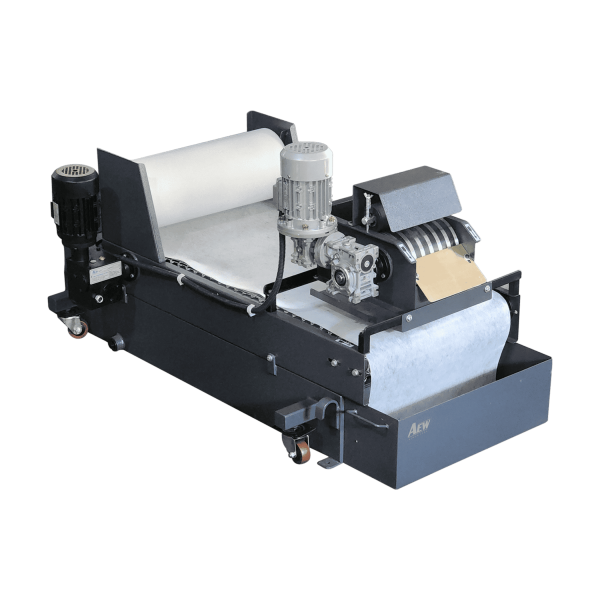

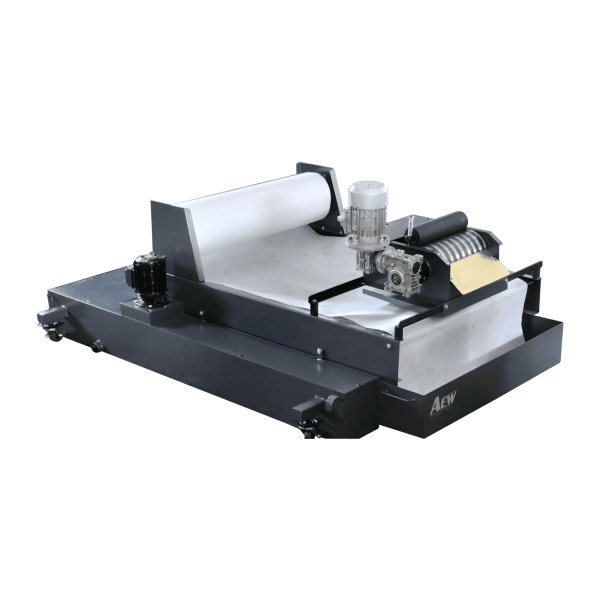

Paper Band cum Magnetic Separator

- Amba Engineering Works

- Paper Band cum Magnetic Separator

ABOUT US

Paper Band cum Magnetic Separator

The Paper Band Cum Magnetic Separator is a highly efficient filtration system that combines magnetic and paper media to remove both ferrous and non-ferrous particles from coolant. Designed for use with precision machines like CNCs, grinders, and milling machines, it ensures cleaner coolant, longer tool life, and reduced machine wear.

Paper band coolant filters are a type of filtration system used for removing contaminants and impurities from coolant fluids in various industrial processes. These filters consist of a paper band that is specifically designed to trap and retain particles, dirt, and debris present in the coolant. As the coolant flows through the filter, the paper band effectively captures and holds onto these unwanted substances, ensuring that the coolant remains clean and free from harmful elements.

FEATURES

Dual Filtration System

High Filtration Efficiency

Improves Coolant Quality

Suitable for Precision Machines

Automatic Operation

Reduces Maintenance Cost

Compact & Sturdy Design

Paper band coolant filters are a type of filtration system used for removing contaminants and impurities from coolant fluids in various industrial processes. These filters consist of a paper band that is specifically designed to trap and retain particles, dirt, and debris present in the coolant. As the coolant flows through the filter, the paper band effectively captures and holds onto these unwanted substances, ensuring that the coolant remains clean and free from harmful elements. This helps to maintain the overall efficiency and performance of the machinery and equipment that rely on the coolant for their operation. Paper band coolant filters are known for their high filtration efficiency and are commonly used in applications such as metalworking, machining, and other manufacturing processes where coolant quality is crucial.

The contaminated coolant liquid is first passed through the magnetic coolant filter which separates almost 95% of the magnetic ferrous particles. The liquid further passes through filter paper where all the nonferrous particles like grinding grit, stainless dust, brass or aluminum sludges are filtered. As the porosity of paper gets filled up due to accumulates the liquid level rises. This triggers the float switch which starts the geared motor and fresh coolant filter paper from the reel is pulled forward automatically. Now the liquid passes through the fresh coolant filter paper and float switch shuts down the paper band filtration system.

Paper band cum Magnetic coolant Clarifier offer the excellent means of filtering both ferrous and nonferrous particles. Where high degree of purification id required and contaminates differ in from, size and composition. Paper band Filtering system as a rule gives best results. Paper band filters are recommended for Grinding, Honing, Transfer lines and Machining center. It also can be used for rolling mills for filtering coolant which helps to improve the surface finish to the sheets.

The drive of the drum is achieved by double reduction worm and worm wheel. The worms are made in high carbon steel, hardened and ground which run on sealed ball bearings. The worm wheels are made in high wear resistance materials. An oil indicator is provided to ensure the level of oil in the gear box. This box is designed for continues and trouble free running for years.

- High efficient way of filtration guarantees fine finish, dimensional accuracy, increased tool life. Keeps your machine clean & reduces costly machine down time for periodical cleaning.

- Avoids bacterial growth and wastage of expensive coolants.

- Since the complete filtration system is automatic, No manual attention is needed

- where heavy stock removal increases the temperature of the coolant. This system of filtration -due to sufficient exposure to air helps to control the same.

| No. | Capacity In LPM (lit/Min) | Emulsion | L | LT | W | WP | TANK CAP. |

|---|---|---|---|---|---|---|---|

| 1 | 50 LPM | 50 | 1100MM | 1300MM | 550MM | 450MM | 150 LTRS |

| 2 | 65 LPM | 65 | 1200MM | 1400MM | 800MM | 700MM | 200 LTRS |

| 3 | 100 LPM | 100 | 1600MM | 1800MM | 800MM | 700MM | 300 LTRS |

| 4 | 150 LPM | 150 | 1600MM | 1800MM | 1000MM | 900MM | 375 LTRS |

| 5 | 200 LPM | 200 | 2000MM | 2200MM | 1000MM | 900MM | 440 LTRS |

| 6 | 300 LPM | 300 | 2300MM | 2500MM | 1000MM | 900MM | 575 LTRS |

| 7 | 400 LPM | 400 | 2200MM | 2200MM | 1470MM | 1370MM | 750 LTRS |